Mineral Plaster Technology LITECLAD System

We believe in healthy, durable building systems that respect sustainable building principles and provide economical solutions that lead the industry.

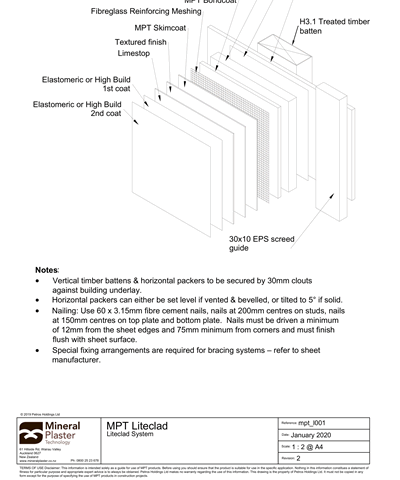

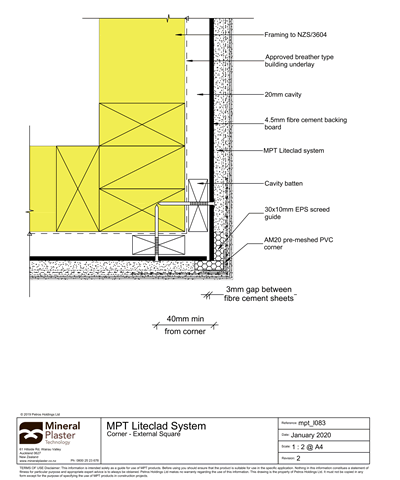

LITECLAD is an insulating plaster render designed as a stronger substitute for solid plaster applications, or as an insulating render over brick, block and masonry systems. It is made of cementitious breathable mineral plasters, alkali resistant fibreglass mesh and assorted PVC flashings and trims. It contains perlite as a natural insulating material and is designed to be used as an external wall cladding system for residential and light commercial buildings.

LITECLAD comes as a dry-mixed bagged product to ensure mic consistency, is pumpable, and can be applied in high-build applications up to 10mm thick per layer.

LITECLAD - when installed and maintained in accordance with the instructions provided by Mineral Plaster Technology will meet the provisions of the New Zealand Building Code, including clauses:

- B1, Structure;

- B2, Durability;

- E2, External Moisture;

- C3, Spread of Fire; and

- F2, Hazardous Building Materials.

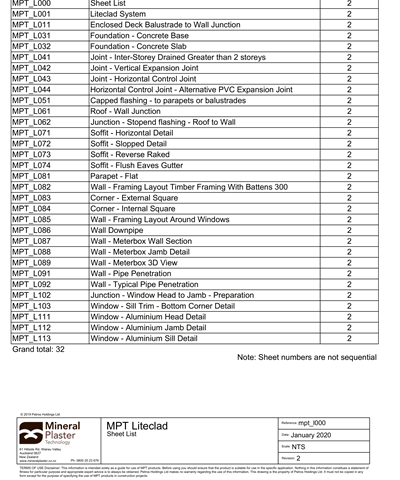

MPT LITECLAD is a four (4) coat plaster system incorporating embedded fibreglass reinforcing mesh and selected finish coats.

MPT LITECLAD must have a coat of efflorescence-blocking primer and 2 coats of high-build or elastometric paint.

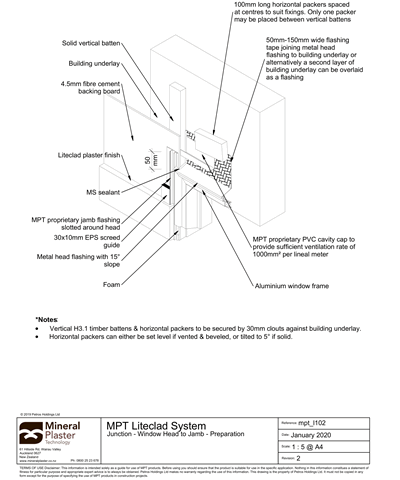

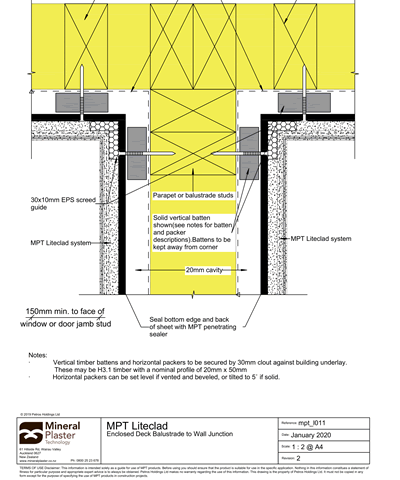

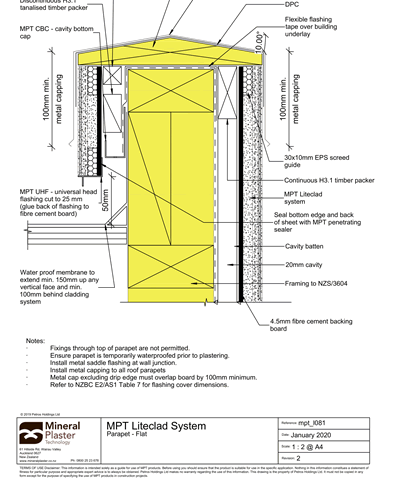

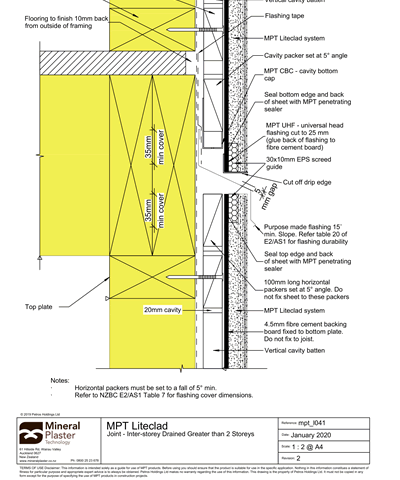

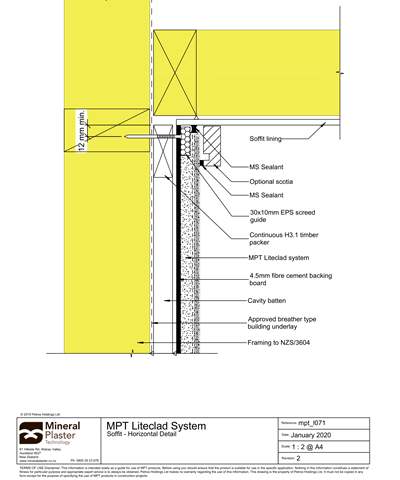

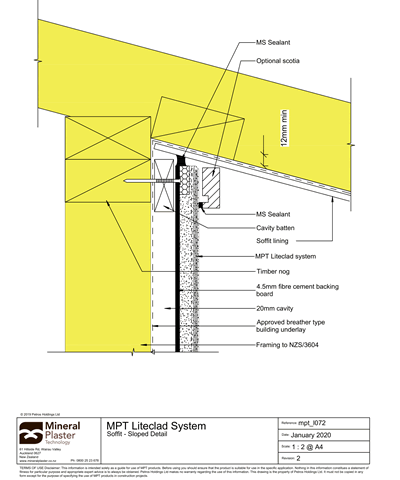

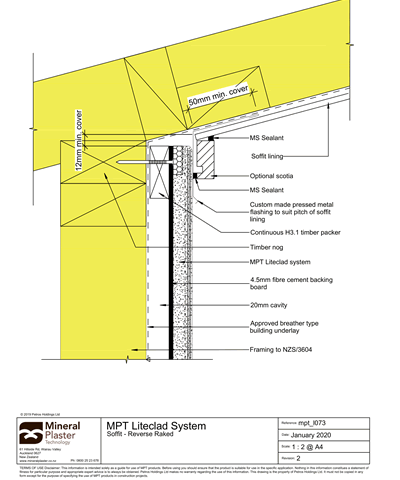

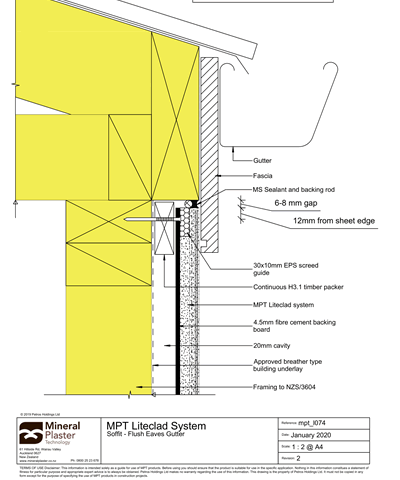

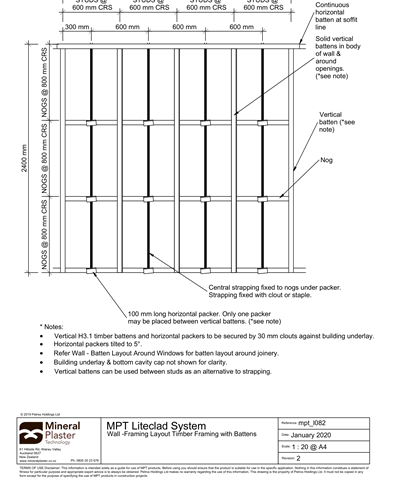

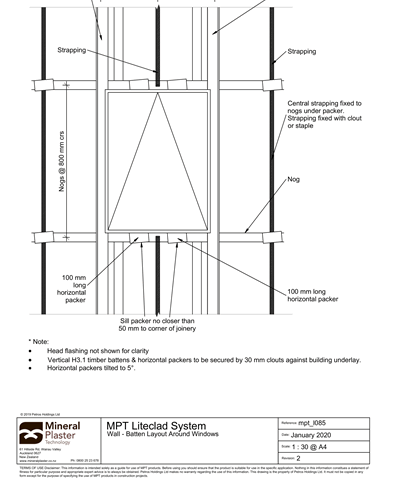

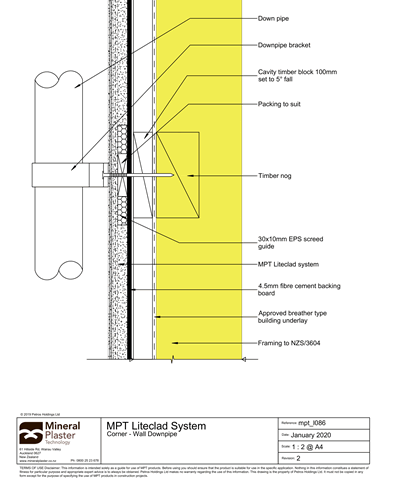

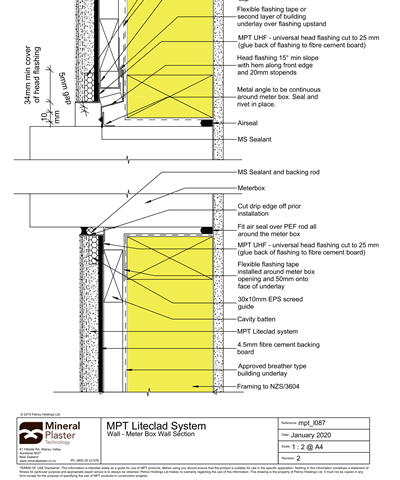

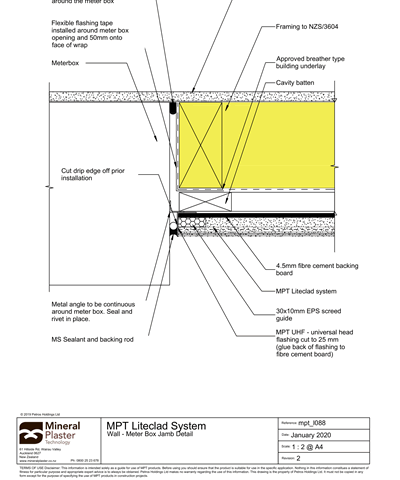

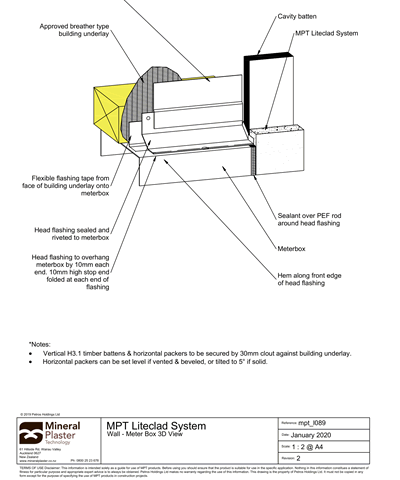

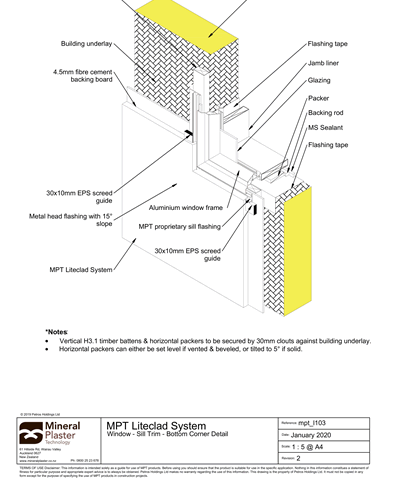

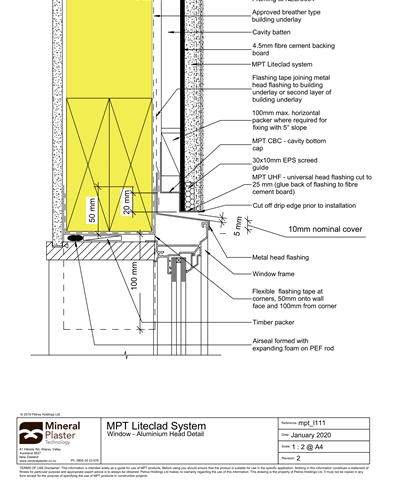

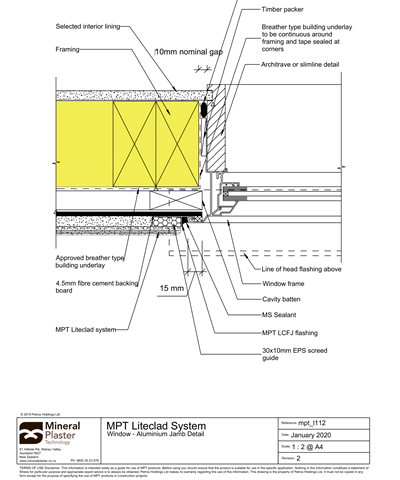

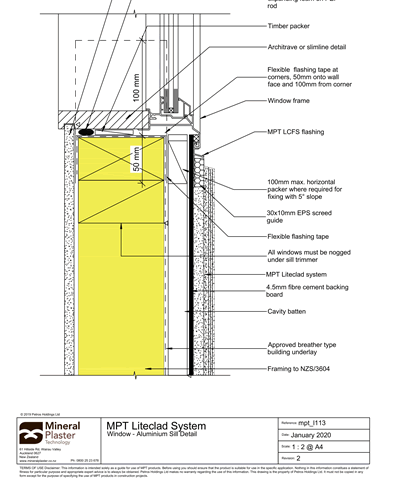

The LITECLAD specification covers the use of 4.5mm fibre cement board as a rigid backing for plastered claddings using cavity construction method for the exterior of buildings which fit within the scope of NZBC Acceptable Solution E2/AS1.

The LITECLAD system may be used externally over a cavity system, or may be direct-fixed internally.

LITECOAT render may also be used directly over brick, block and masonry systems as an insulating render over which BONDCOAT embedded with mesh, then SKIMCOAT and a finishing render may be used.

Substrate Preparation

Ensure that the substrate is sound, dry and free of any dirt, dust, mould, fungus, grease or other contaminants.

MPT Amberseal must be applied by roller or spray to the total surface area on both sides of the fibre cement board, or on the face of the masonry/brick/block surface. The system consists of a 10mm thickness of MPT LITECOAT applied directly to the sealed fibre cement sheets (or masonry system), then 2-3mm of MPT BONDCOAT reinforced with fibreglass mesh, then a 1-2mm layer of MPT SKIMCOAT, then 1-4mm thick layer of MPT FLOATCOAT or ADOBECOAT as desired.

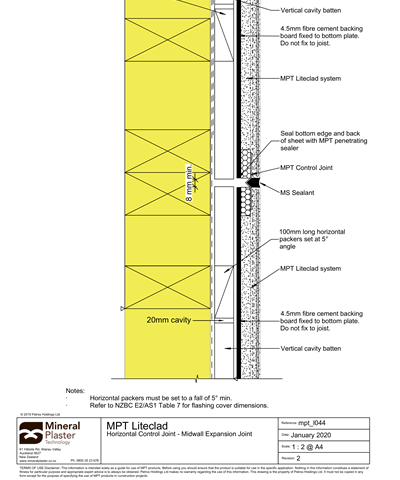

Structural control or expansion joints should be designed in accordance with the substrate manufacturer's technical specifications and installed in accordance with the LITECLAD Technical Manual. MPT vulcanised PVC control joints are to be filled with a BRANZ appraised MS sealer (we recommend and supply Sabre-Seal MS) and are not to be covered by the finishing textures.

The main component of MPT LITECLAD is MPT LITECOAT plaster which provides a tough, durable and crack resistant base when used in conjunction with MPT BONDCOAT embedded with fibreglass reinforcing mesh. LITECOAT itself is also a chopped-fibre reinforced render.

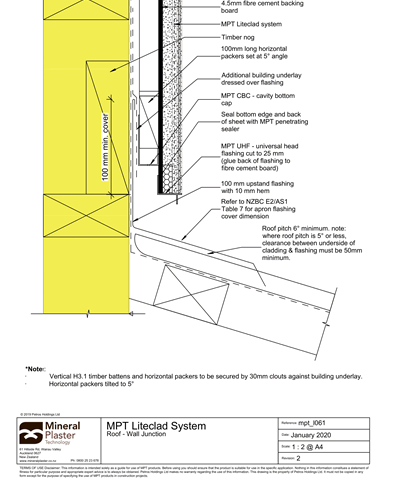

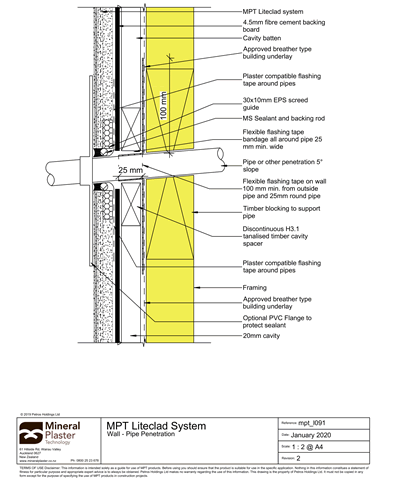

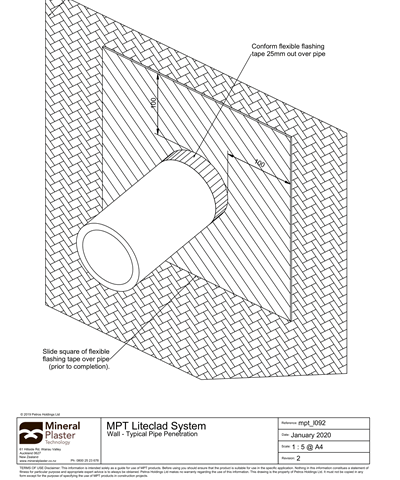

The fibre cement-based LITECLAD system incorporates a primary and secondary means of weather resistance (first and second line of defence) against water penetration by separating the cladding from the external wall framing with a nominal 20 mm cavity. The cavity allows for external drainage of any ingress of water that may get past the external skin and any remaining moisture to dry by evaporation.

All Plaster must be over-coated with 1 coat of efflorescence-blocking primer and 2 coats of high-build or elastomeric paint.

It should be noted that the colours chosen for the LITECLAD system need to comply with the NZ Building Code and must have an LRV (Light Reflectance Value) of 40% or higher.

All plaster finishes and/or texture and paint colour samples must be signed off by the architect or owner prior to application.

Mineral Plaster Technology requires that all Mineral Plaster Technology products are applied by Approved MPT Applicators to ensure the correct application and integrity of the system for warranty requirements.

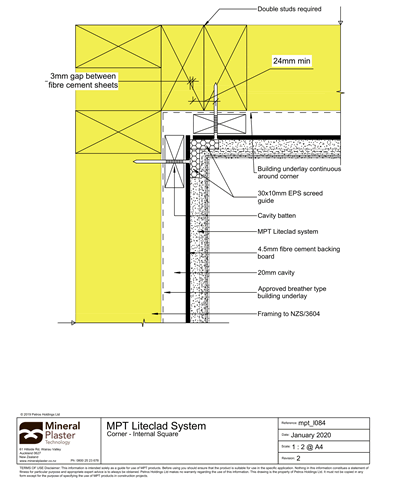

CAD FILE DOWNLOADS

Select Category

- pdf version

- pdf version - dwg version

- dwg version - dwg compatibility version

- dwg compatibility version

MPT

Plaster

Systems

Talk to us about your project

0800 25 23 678